IBC Instruction Manual

We put quality first, providing only the best products.

Drum Instruction Manual

-

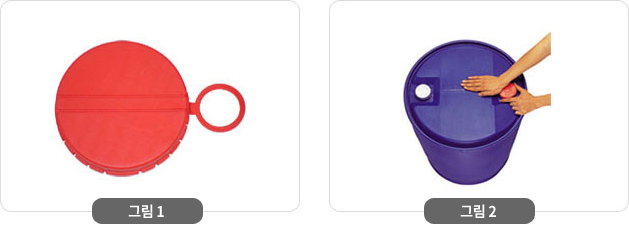

How to Install a Drum Cap

- Align the threads of the CAP and the inlet opening and lock them tightly

by hand (if you turn them slightly counterclockwise and then clockwise,

they will be easily installed). - Use a torque wrench to further lock it as shown in Figure 2 (minimum

torque: 3.5kgf•m).

※ However, the minimum torque is based on testing with water. Please

note that the minimum torque may vary depending on the chemical

used. - Excessive tightening may cause the O-Ring to wear out, cause the CAP

to spin, and make it impossible to install the seal cap. - If you lock the CAP only by hand, the substance inside may leak. So,

please make sure to use a torque wrench to lock the CAP.

- Align the threads of the CAP and the inlet opening and lock them tightly

-

How to Install a Drum Seal Cap

- After locking the CAPcompletely, fasten the seal cap by tapping

the left and right sides of the seal cap handle with a rubber mallet

(however, do not use a rubber mallet on the handle for removing

the seal cap). - There is a risk that it may not be installed easily or may be damaged

if a momentary impact is applied to the part.

- After locking the CAPcompletely, fasten the seal cap by tapping

-

Precautions

- A product filled with a substance should always be stored and handled upright (especially vent cap products).

- If the bung is not installed correctly, the seal cap may be damaged causing leakage ofthe substance inside.

- When loading on the pallet, the container must be placed suchthat it does not fall off the pallet (there is a risk of the container being crushed).

- During storage, avoid exposure to direct sunlight (ultraviolet rays) and store at room temperature in a well-ventilated area (ultraviolet rays cause

deterioration ofthe physical properties of the container).