Technology

We put quality first, providing only the best products.

Quality Assurance

Quality Guarantee

We produce top-quality productsthat help maximize customer profits through customer satisfaction and quality management. Clover Chemical’s products guarantee the highest quality through rigorous testing and inspection.

-

Basic Property Test of Raw Materials

We apply ananalysis methodthat tests the melt index of raw materials and reflects it in production. This provides important data for controlling the operating conditions.

-

Drop Test

The product and substances inside are frozen to -18°C or lower, dropped from a specified height, and inspected for damage or leaks.

-

Compression Test

This is atest that applies a load to the top of a container andinvestigatesthe container for any deformation and weak areas. It is carried out during product development and initial production.

-

Stack Load Test

A load equal to the total weight when loaded with 3m is applied to the container that is being transported or stored. Followingthis, the container iskept at 40°C for 28 days to maintain stability and check for damage or leaks.

-

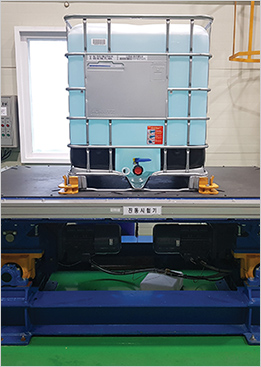

Vibration Test

Considering the possibility of vibration occurring during transportation, the IBC is filled with water and vibrated at an amplitude of 25.0 mm for 1 hour to check for damage or leaks.

-

Air Tightness Test

Air pressure higher than the pressure specified for the product is applied to the container to check for air leakage.

-

Hydraulic Test

The product is filled with water and water pressure higher than the specified pressure is applied to inspect for damage or leaks.

-

Leak Test

We conduct a full inspection to check the product for any leaks.

-

Durability Test

This is a test in which a container is filled with a chemical substance and investigations are conducted to check for any reaction or changes in the containerin harsh environmental conditions.

-

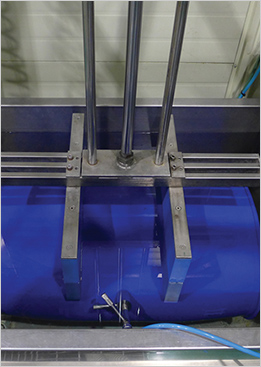

Tilting Test

The container is fixed on a tilting machine and checked for water leaks by applying movement that may occur during transportation (reciprocating movement of 20 degrees left and right, 25 times/min).