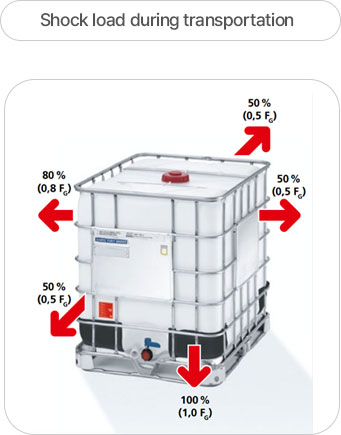

- When moving, please be careful not to cause damage to the IBCwith scratches from the fork or external shock.

- When moving the IBC with a lower lifting structure, avoid connecting a chain to the grid or tie-bar.

Product Info

We put quality first, providing only the best products.

IBC Containers

Strengths of IBC

- Maximized utilization of loading space

- IBC 4,000L (4-level loading)

vs drum 2,400L (when using the same area)

- Operational convenience when filling

/discharging - 1 1,000L IBC discharge time: 15 minutes (1 person)

vs. 5 200L drums discharge time: 90 minutes

- Reduction of transportation costs

(for a 20ft container) - IBC 18,000L (18 ea)

vs drum 16,000L (80 ea)

Handling Guide

(Intermediate Bulk Container)

※ Packaging, loading, transport and handling of all dangerous goods must comply with the IMDG Code.

Pouring and Storage

- Open the upper screw cap, pour the substance from above, and check the sealing before transport.

- The maximum packaging capacity of this container is 1,000L.

- Extremetemperatures should be avoided during packaging. The highest permitted operating temperature (for sealing, storage, transport, unloading, cleaning, etc.) is 70°C, and the lowest permitted operating temperature is -40°C.

- Our IBCs are developed and configured to transport and store substances on a first-time, single-use basis.

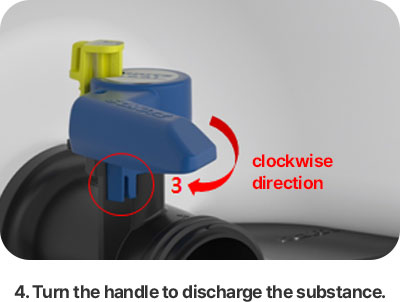

- We recommend that you empty the substance as quickly as possible after first opening the discharge valve.

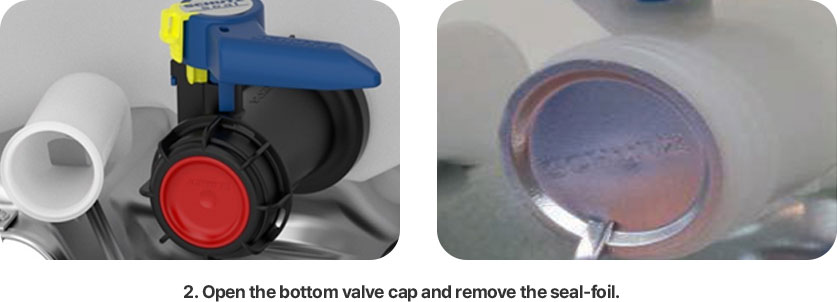

How to Discharge Substances

How to Seal the Container

After filling the IBC, tighten the top screw cap by hand and then use the JIG to turn it clockwise to the appropriate torque or angle to seal it (see below).

| 구분 | Thread designation |

Minimum locking torque when the container is filled with a substance [N.m] |

|---|---|---|

| Screw cap DN 150 | S 165 X 7mm | 75 |

| Screw cap DN 225 | S 245 X 6mm | 105 |

Method of Loading

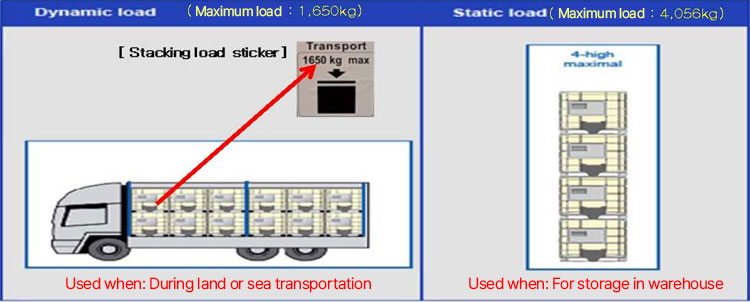

Maximum Load

Precautions

- When stacking, do not exceed the prescribed upperloading weight based on the lowest IBCs.

Container Finishing

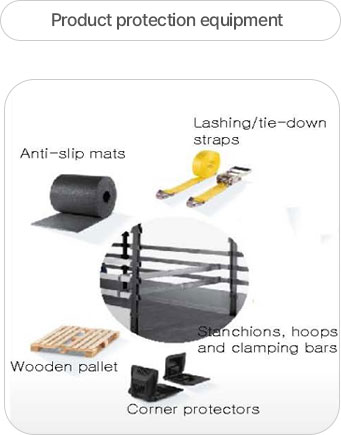

IBCs inside a container

- Fixing it in the left and right directions: Be sure to nail the empty space in the first tier of the container with wood.

- Fixing it in the vertical direction: Finish the sling with a belt or rope, and make sure to tie it in a △ shape.

- Fastening it back and forth: Use wood and slings at the ends of the container to minimize movement of the product.

- Makesure to stack products in a zigzag manner (up to 18 IBCs can be loaded into a 20-foot container).

- Fixing it left and right: Insert wood into empty space and finish it with nails.

- Fixing it in the vertical direction: Minimize movement of the first and second stages of the products.

movement of the first and second stages

of the products, it is finished with diagonal

and triangular bundling (see the red area).

- Fixing it back and forth: Minimize forward/backward movement during transportation of the product.

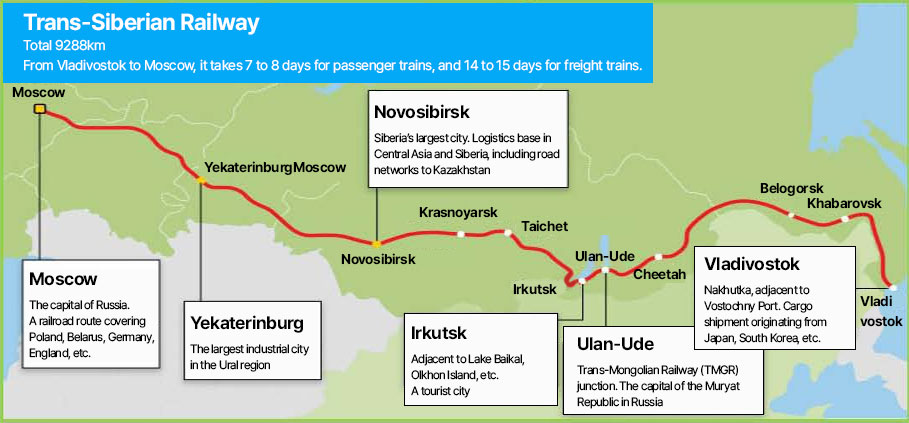

Transport on the Siberian Railroad (TSR)

When transporting our IBCs through the Trans-Siberian Railway, please make a noteof the following.

- For heavy goods (weight per packaging unit exceeding 1.5 tons) or dangerous goods, it is necessary to obtain prior approval from the Russian Railways after special shoring work.

- Even for non-dangerous goods, special shoring operations are characteristically recommended for transport on the Siberian Railway to minimize damage to IBCs caused by long-term stress.

Fill the empty space of the container with wooden planks and secure them with ropes or belts to prevent shaking during transportation. Finally, wood finishing is required.

- The above shows an example of container finishing work;however,it may differ slightly from actual operations. For details, please refer tothe latest version of the Russian Railways’ securing instructions.

Product Protection Equipment